AME System Project Management

From the Concept to a Product Design

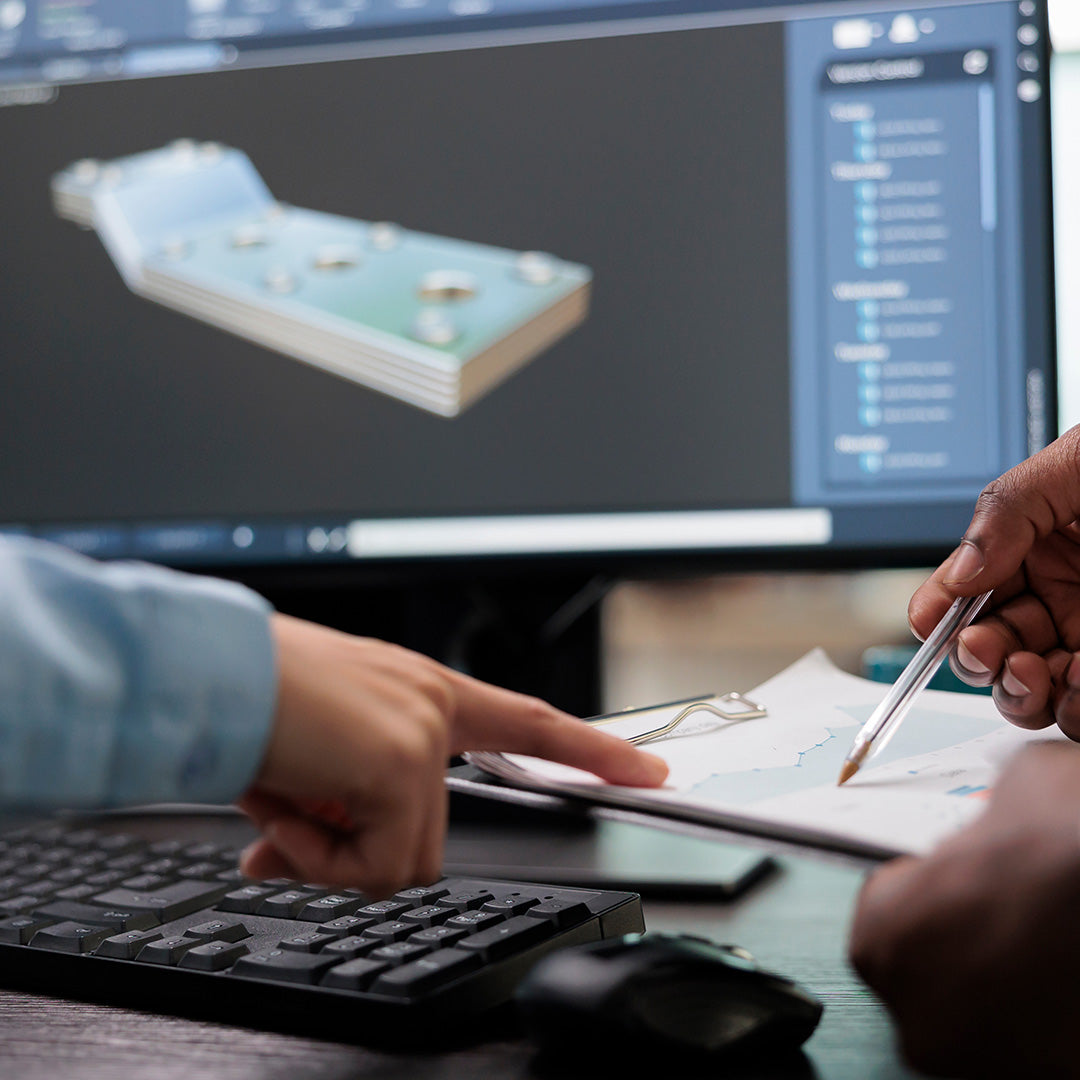

3D CAD (Computer-Aided Design) product design is a critical process in modern manufacturing and product development at AME System, enabling designers to create complex, accurate, and optimised designs efficiently. Here’s an overview of how it works.

AME System Tools

CAD Software: At AME we use popular CAD software tools. They offer a range of functionalities to create, modify, analyse, and optimise designs.

Parametric Design: CAD systems use parametric modelling, where dimensions and design constraints are defined, allowing for easy modifications and iterations.

AME System Custom Design

Idea Generation: The design process begins with conceptualising the product. Our designers sketch ideas and develop initial concepts.

3D Modelling: Using CAD software, designers create a three-dimensional model of the product. This model is a virtual representation that includes all the details of the product’s geometry.

Custom Design and Engineering

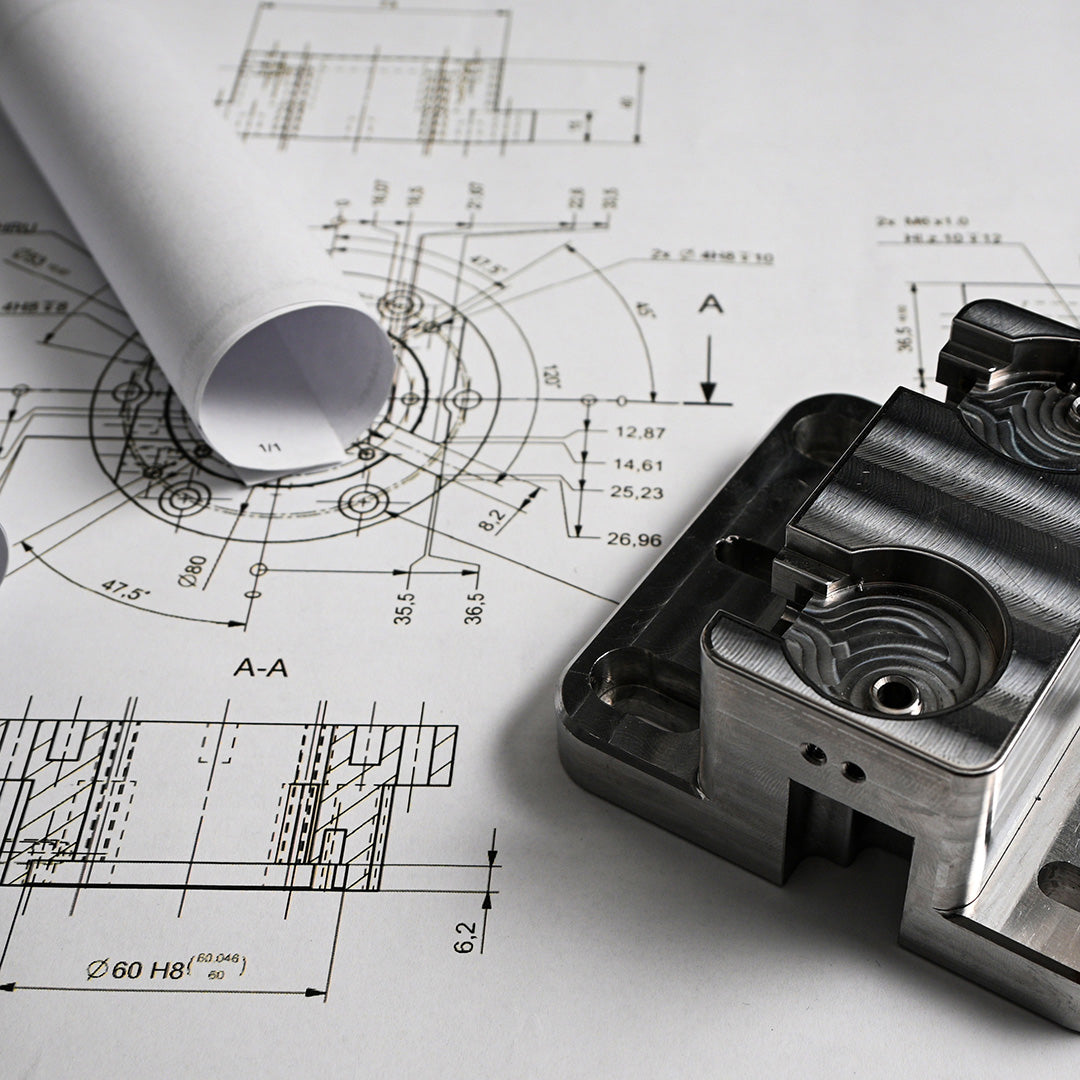

- Precision and Detailing: In the next phase our designers add precise dimensions, tolerances, and material specifications to the 3D model. This step ensures that our design proposal meets all your functional and manufacturing requirements.

Final Design and Documentation

Design Refinement: Based on testing and analysis, the design is refined and optimised for production.

Technical Drawings: Detailed technical drawings and documentation are created, including all specifications required for manufacturing.

AME System 3D printed elements

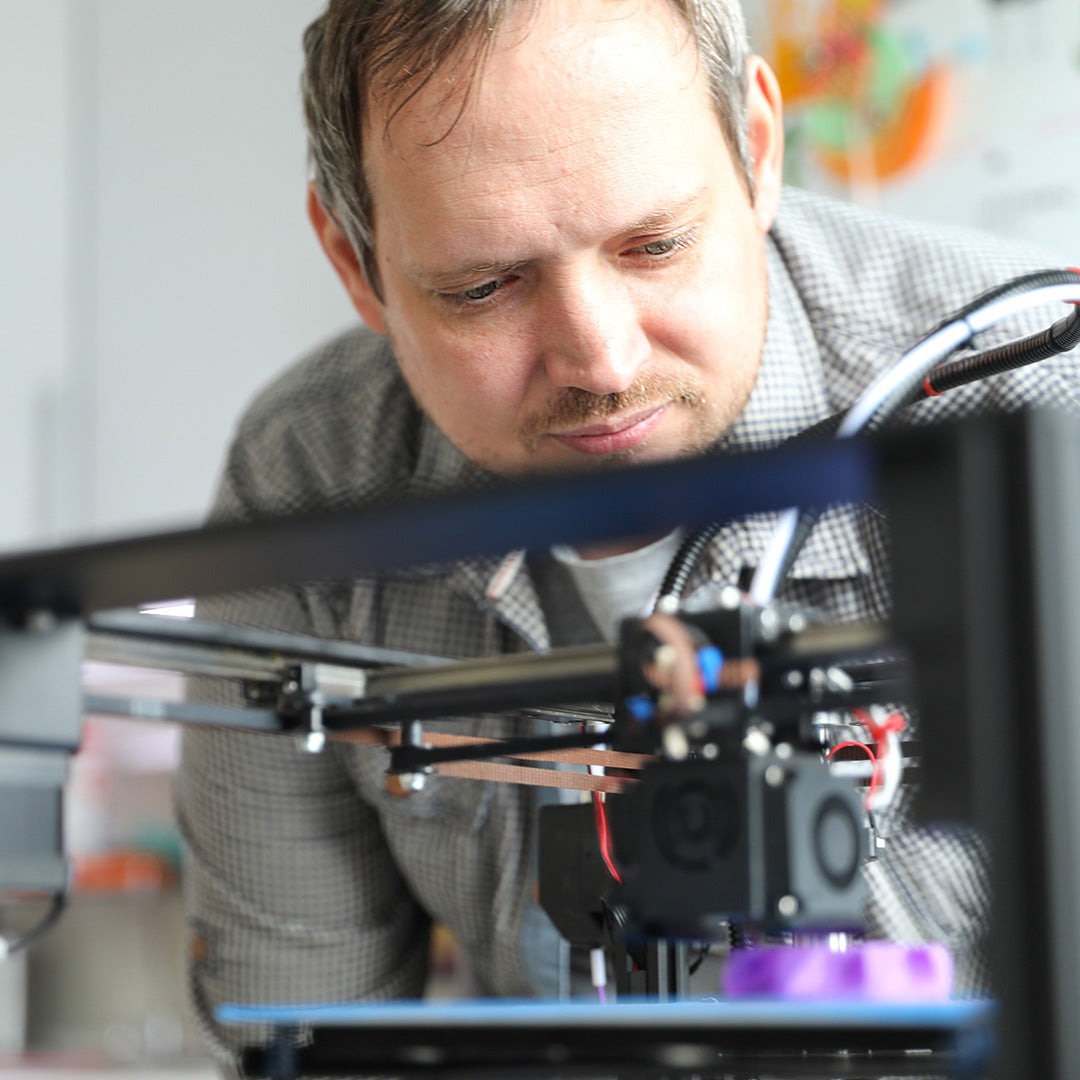

3D Printed Components

3D Printing: At AME System, we use 3D printing to rapidly prototype small components such as endcaps, plastic hinges, and detailed fittings. This approach allows us to quickly test individual parts for fit and function within larger assemblies, supporting an efficient and precise design process.

AME System Production and Manufacturing

CNC Machining: CAD models are used to program CNC machines for manufacturing the product parts.

Quality Control: Throughout the production process, CAD data is used for quality control, ensuring that the manufactured parts meet the design specifications.

Benefits of 3D CAD Product Design

Accuracy and Precision: CAD software provides high precision and accuracy in AME System design, reducing errors and ensuring consistency.

Visualisation: 3D models allow for better visualisation of the final product, making it easier to detect potential issues early in the design process.

Efficiency: CAD speeds up design and simplifies changes, allowing us to complete projects faster.

Cost Savings: By identifying and solving design problems early, CAD helps us in minimising costly revisions during the manufacturing stage.